Color Engineering

Introduction

Plasmonic metal nanoparticles have unique optical, electrical, and thermal properties that make them useful in a wide variety of applications ranging from antimicrobial coatings to molecular diagnostics. One application that takes advantage of the unique optical properties of metal nanoparticles is color engineering – where custom nanoparticle formulations are designed to absorb and scatter specific wavelengths of light to generate a color. Plasmonically generated colors are unique in that the optical properties of metal nanoparticles can be tuned by changing size, shape, and material composition (see our Plasmonics Knowledge Base for more details). While researchers have known that nanoparticles can be used in color engineering applications for many years (in fact, one of the first examples of this application is the gold nanoparticles that were used to color stained glass red in medieval times), commercial applications have been limited by the cost of plasmonics materials. Advances in scaled manufacturing processes now make it possible to incorporate these materials into paints, plastics, cosmetics, and other coatings and composites to impart unique optical properties to a wide range o f materials. NanoComposix has partnered with a number of commercial partners to fabricate OEM nanoparticle formulations for specific applications in which a precise color effect is required.

Plasmonic Nanoparticle Optical Properties

The vibrant colors of plasmonic nanoparticles occur because the conduction electrons on the surface of each nanoparticle vibrate when excited by light at a specific wavelength. These vibrations result in extremely bright colors that can be tuned by changing the particle size and shape (Figure 1). For a brief tutorial describing this effect, and how nanoparticle colors can be tuned, please refer to our Plasmonics Knowledge Base article.

Figure 1. Solutions of plasmonic nanoparticles with controlled size, shape, and composition.

Plasmonic Nanoparticles vs. Standard Pigments and Dyes

Standard commercial pigments and dyes either absorb or scatter (reflect) wavelengths of light. In order to change the color of a pigment, the chemical formula must be modified. This reduces the tunability of pigments, and makes subtle changes of color difficult to engineer (typically a new molecule must be used for each new color). Additionally, pigments tend to either scatter or absorb light, but rarely do both.

Nanoparticles, on the other hand, can be engineered to absorb, scatter, or both absorb and scatter. Since the particle colors depend upon size and shape, very subtle changes can be made without requiring a new formulation to be developed. For instance, if a customer desires a green-blue color (like a mix of the two right-most vials depicted in Figure 1 which correspond to 120 nm and 60 nm silver nanoplates), we can fabricate 90 nm silver nanoplates for the application. Likewise, if only very small changes in color are required, the dimension of the nanoparticles can be increased or decreased by just a few nm. This level of control provides an unprecedented level of tunability which cannot be achieved using standard dye and pigment technology.

Perceived Color

Nanoparticles appear certain colors because they reflect (scatter) and absorb specific wavelengths of visible light. Light which appears white is a roughly equal mixture of the wavelengths of light that can be perceived by the human eye (roughly 400-700 nm, Figure 2).

When light interacts with a nanoparticle formulation, light is either absorbed or scattered, allowing the light that continues on to reach an observers eye to appear a specific color – often referred to as the “perceived color”. The following sections describe how absorbing and scattering nanoparticles interact with light.

Perceived Color From Nanoparticle Absorption

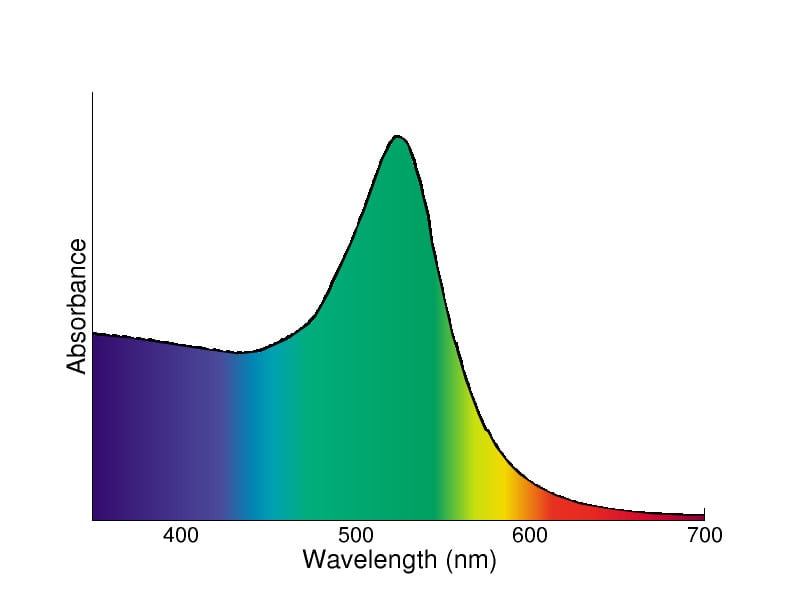

When nanoparticles absorb light, the observer sees the light that is transmitted through the formulation, causing the observer to perceive light that is the opposite color than the absorbed color. For example, small gold nanoparticles absorb blue and green light (Figure 3).

Figure 3: Absorption spectrum of 13 nm gold nanoparticles. The inset depicts the colors that are being absorbed- note that the nanoparticles absorb primarily green and blue photons.

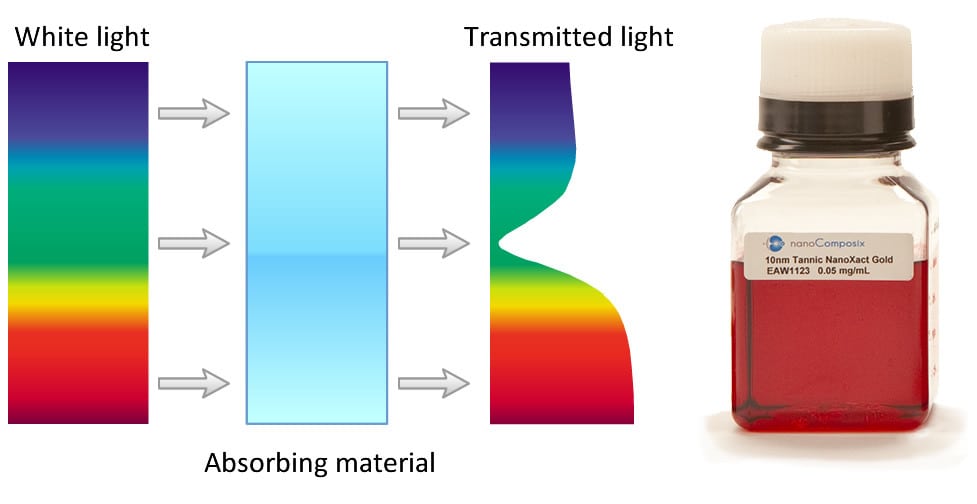

When white light interacts with these particles, blue and green light is absorbed and red light is transmitted through the material. To the eye of the observer the nanoparticle formulation appears red.

Figure 4: Schematic of white light interacting with small gold particles (left). Note that for particles with the absorption spectrum displayed in Figure 3, red light is transmitted and seen by the observer. This causes small gold nanoparticles to appear red (right).

Perceived Color From Nanoparticle Scattering

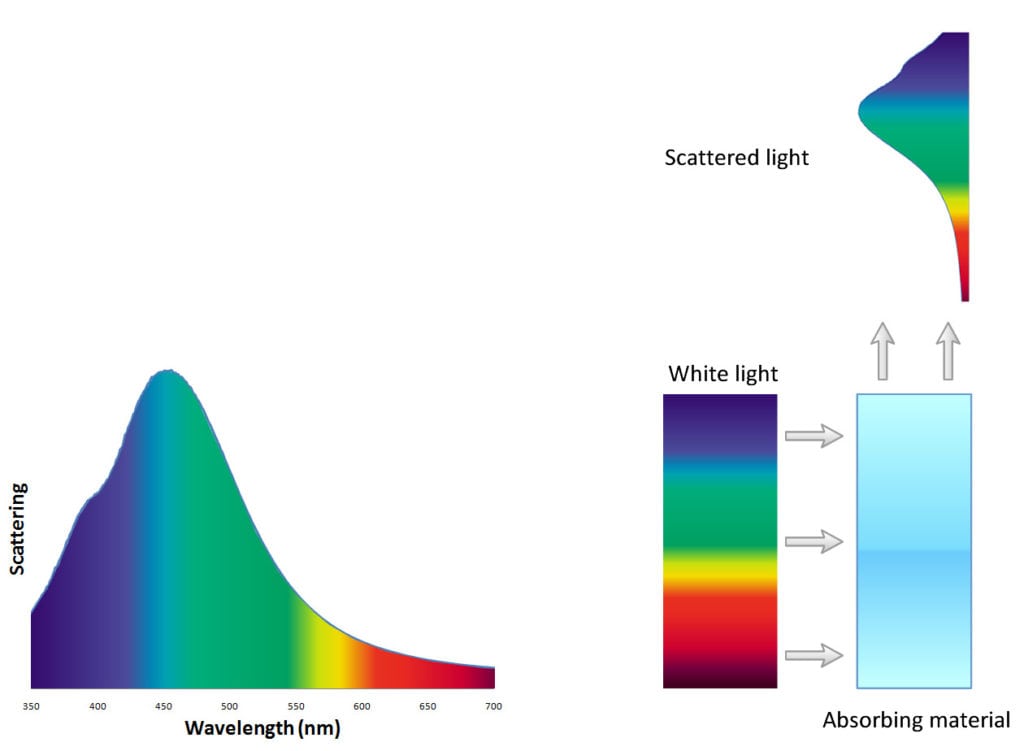

When nanoparticles scatter light, the observer sees the light that is scattered from the nanoparticle formulation, causing the observer to perceive light that is the same color as the scattered color. For example, large silver nanoparticles scatter blue light (Figure 5).

Figure 5 (left): Scattering spectrum of 80 nm silver nanoparticles. The inset depicts the colors that are being scattered- note that the nanoparticles scatter primarily blue and green photons. Figure 6 (right): Schematic of white light interacting with large silver particles. Note that for particles with the scattering spectrum displayed in Figure 5, blue light is scattered and seen by the observer.

When white light interacts with these particles, blue light is scattered from the material and into the eye of the observer (Figure 6).

Bichromic Materials

Nanoparticles can be engineered to both absorb and scatter specific wavelengths of light, allowing formulations with unique color combinations to be fabricated (Figure 7). When a formulation can be perceived as a different color depending upon where the observer is standing (or which angle the light is shining from), we call them bichromic (for two color formulations) or polychromic (for three or more colors).

Figure 7: Plasmonic nanoparticles can simultaneously absorb and scatter light to provide a bichromic color effect. Here gold nanoshells (a silica core surrounded by a thin gold shell) absorb green and red light, causing transmitted light to appear blue (bottom of vial and shadow), and scatter red light, causing scattered light (top of the vial) to appear red.

Formulation Development

NanoComposix has the manufacturing technology to fabricate custom formulations at commercially relevant scales and price points. With our extensive experience fabricating hundreds of different variants of nanomaterials coupled with our understanding of nanomaterial optical properties (aided by numerous validated numerical modeling codes) we can help engineer unique optical effects that are unobtainable with standard dyes and pigments. To discuss your application with a nanoComposix scientist, please contact us.